Tests and verifications on electrical and mechanical safety

All tests are performed to assess the conformity of the products to the safety standards of both IEC and UL. We carry out tests to make sure that the hazardous internal parts of the products are unaccessible, dielectric strength tests to assess the resistance of the insulation, and leakage current measurement tests.

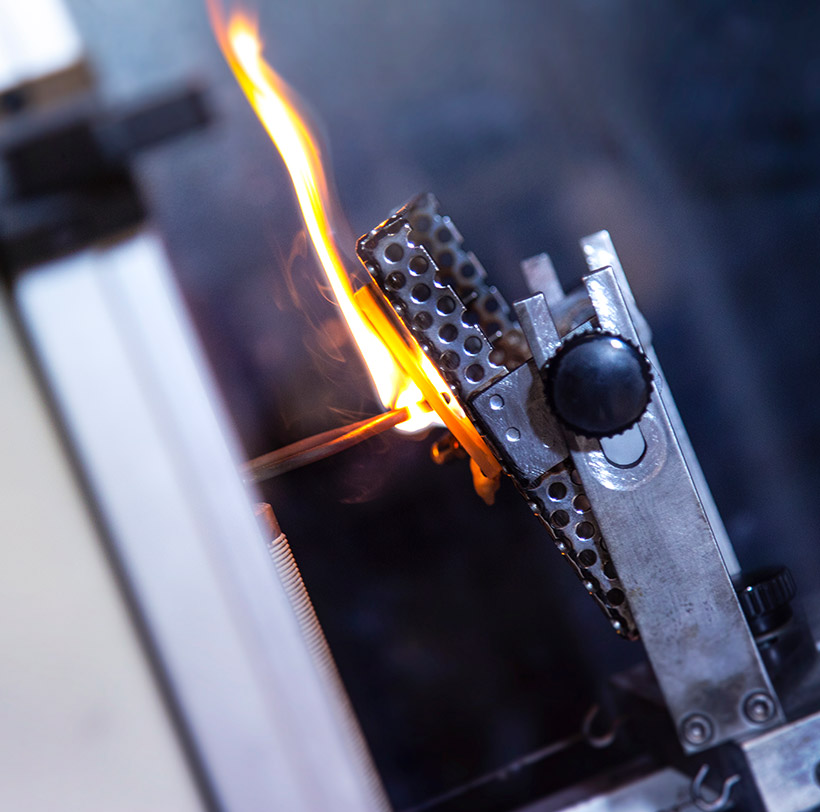

Tests on plastic materials

Flame and heat resistance tests are carried out: needle flame test, incandescent thread test, sphere pressure test.

Component temperature, installation and engine

We check whether the components above the hob, both gas and induction ones, are working at the right temperature. We can test the correct installation of the products to the fullest: 8 hours a day, 5 days a week, from one week to 3 months. Checks are carried out when the product is on and running or when the product is off, to prevent the hood blower from subtracting heat and thus reaching the maximum possible temperature.

Since 1893 UL has been providing expertise in strategic businesses for the promotion of safe living and working environments around the world.